One of the most common questions we are asked by our customers is what is the R-Value of this pipe insulation. This is an easy question to answer for building insulation and board insulation products due to product surfaces being flat. With pipe insulation, the surface is not flat, but curved which makes calculating the R-value much more complex. In this guide, we are not going to get into the math equations of calculating the R-value, we are simply going to explain the following:

1. What is the basic definition of R-Value?

In very basic terms, R-Value can be thought of as Insulating Power or Thermal Resistance. The higher the R-value, the greater the insulating power. Higher R-values are more effective at maximizing your energy savings.

2. Why Calculating R-Values for Pipe Insulation is different than Building Insulation (flat insulation).

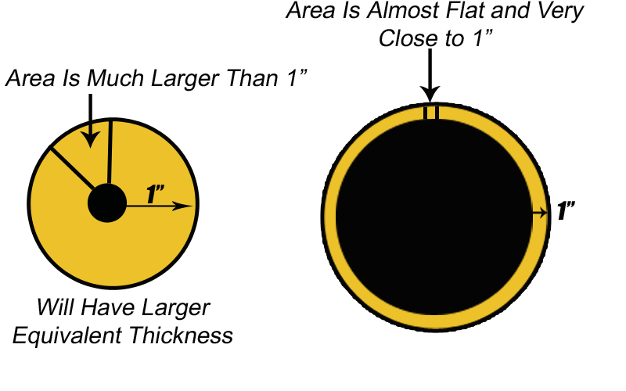

Building Insulation is flat which allows the R-Value to be determined by the actual thickness of the insulation. Pipe Insulation is curved, so the surface area changes depending on the insulation thickness and the size of the pipe. The smaller the pipe and the thicker the insulation, the larger the amount of insulation in that space. In the diagram below, we attempt to show two pipes both insulated with 1" thick insulation. As you can see, a smaller pipe will have a larger insulation area based on the difference between the surface area of the outside of the insulation compared to the surface area of the pipe. The larger pipe will have an area that is very flat which makes the difference in surface areas amost nil and close to 1".

2. Why R-Values for Fiberglass Pipe Insulation differ for different pipe sizes.

As shown in the diagram above, the "Equivalent Thickness" is larger for the smaller pipe.

For example 1 x 1 pipe insulation will have an equivalent thickness of 1.541" while 5 x 1 will have an equivalent thickness of 1.104". The 5 x 1 insulation will be more flat and closer to 1" than 1 x 1 which is almost like having 1-1/2" of flat insulation on it due to the comparison of the pipe size.

3. Why R-Values between different types of pipe insulation products differ based on mean temperature.

The R-Value of an insulation is broken down into two factors; a.) the thickness of the insulation and b.) the K-Value of the insulation type at the mean temperature. The lower the K-Value for an insulation material at a certain mean temperature, the better. K-Values will vary based on the mean temperature ( For example, at a mean temperature of 100°, Fiberglass will have a K-.24 while at 400°, Fiberglass will have a higher K of .39. So the R-Value of fiberglass at 100° will be higher than it's R-Value at 400°.

GLOSSARY:

Mean Temperature = When we discuss the mean temperature, this is the temperature of the pipe and the temperature of the ambient air (room temp) added together and divided by two.

For Example: An exhaust pipe has a temperature of 325° and the room temperature is 75°, the mean temperature would be 400/2 = 200°.

K-Value = K-Value is based on the insulation material type and the mean temperature. The lower the K-Value the better the R-Value will be.

Equivalent Thickness = Equivalent thickness is that thickness of insulation, which, if installed on a flat surface, would yield a heat flux equal to that at the outer surface of the cylindrical geometry.

EQUIVALENT THICKNESS LIMITS

The following will show the pipe size per insulation thickness where the equivalent thickness transcends back to the actual insulation thickness. Most pipe sizes smaller than the ones posted below will have an equivalent thickness that is greater than the actual pipe insulation thickness.

1/2" thick = 2 x 1/2 and below

1" thick = 4 x 1 and below

1-1/2" thick = 12 x 1-1/2 and below

2" thick = 16 x 2 and below

R-VALUE CHART AT 75° FOR FIBERGLASS PIPE INSULATION

PIPE INSULATION THICKNESS

| Pipe Size |

1/2" |

1" |

1-1/2" |

2" |

| 5/8 x |

R 4.5 |

R 9.5 |

R 13.0 |

n/a |

| 1/2 x |

R 3.1 |

R 7.4 |

R 13.2 |

R 18.9 |

| 3/4 x |

R 2.9 |

R 5.8 |

R 10.9 |

R 16.1 |

| 1 x |

R 2.8 |

R 7.0 |

R 11.5 |

R 16.8 |

| 1-1/4 x |

R 2.7 |

R 5.6 |

R 11.9 |

R 14.5 |

| 1-1/2 x |

R 2.5 |

R 6.4 |

R 10.4 |

R 17.8 |

| 2 x |

R 2.8 |

R 6.1 |

R 10.4 |

R 14.5 |

| 2-1/2 x |

R 2.8 |

R 5.9 |

R 11.8 |

R 15.9 |

| 3 x |

R 2.5 |

R 5.5 |

R 9.0 |

R 12.7 |

| 4 x |

R 2.4 |

R 5.5 |

R 8.6 |

R 12.1 |

*Please contact us for any other R-Value info at customerservice@buyinsulationproductstore.com