Purchase Our Products at Our Online Store At: www.BuyInsulationProductStore.com

|

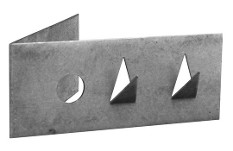

BASS TRAPS: Things to Keep In Mind When Building: - The thicker the panel, the better it will be at absorbing low frequencies (4"+). Low frequency waves can measure over 40 feet in length! The longer a sound wave is, the flatter the wavelength will be at the time of striking your bass trap. By increasing the thickness of the bass trap, you are also increasing the amount of the sound wave that is absorbed in the insulation. A bass trap should be atleast 4" thick with the most effective traps being as thick as 8"! - Refrain from adding extra insulation behind your bass trap panel, open air is actually better. It would seem that adding extra insulation behind the bass trap would be a good idea, however this is not always the case. You are adding to the cost of your panel as well as hurting the bass trap's effectiveness. Leaving an airspace allows the sound wave to strike the bass trap at a higher velocity which results in a higher conversion of energy to heat (absorption). Bass Traps that fill the complete corner are called "SuperChunks" and are made by cutting our panels into triangles and filling the entire corner. - The larger the surface area of the Bass Trap, the better. A size reduction in the 2ft side of our panels to save space is not recommended. If you have a small room to begin with, there is an even more important need for large bass traps. Cutting the panel to 1ft or 1-1/2" feet will greatly diminish the effectiveness of your bass traps.

INSULATION MATERIALS FOR BASS TRAPS There are two types of insulation that are commonly used for bass traps, these are fiberglass and mineralwool. Fiberglass insulation panels are made out of tiny inorganic glass fibers held together by thermosetting resin binder and preformed into rigid board that are 2ft x 4ft rectangles. Owens Corning is the premier manufacturer of fiberglass board insulation in the United States, and their board product is referred to as the 700 Series product line. The 700 Series board comes in different densities (weight of fiberglass per cubic foot). 703 is one of the more economical and efficent products with a density of 3 lbs. 705 is the professional grade acoustic board that has a density twice that of 703 at 6 lbs. Due to the higher density, 705 is much more rigid and firm than the 703 board. Due to this fact, we recommend 703 for framed panels while 705 can be used in frames and non-frame applications. Mineralwool insulation panels are made out of fibers derived from basalt rock and slag. The mineralwool boards also come in the standard 2ft x 4ft rectangle panels. Roxul is the largest mineralwool insulation manufacturers in North America. Roxul makes many different thicknesses and densities, the most common densities are 8 lbs/cf and 4 lbs/cf. Mineralwool panels are considered rigid but they do tend to be a little softer than the fiberglass panels. Mineralwool boards are generally less expensive than fiberglass, which results in a lot of DIY bass traps being comprised of mineralwool from a cost standpoint. PANEL THICKNESS ABSORPTION COMPARISONS The table below shows the acoustical properties showing the performance difference in absorption from 2" thick panels compared to 4" thick panels (or double 2"). For low frequencies, the lowest that the manufacturers test is 125 hz so we use this number as an indicator as to how these materials perform at even lower frequencies. As you can see 4" of material will greatly increase the absorption of your bass traps. We do not have testing from manufacturers for thicknesses over 4" thick, but we have seen testing for independent acoustic panel makers that reflect our belief that 6" thick continues the trend that thicker is better. Cost and space do come into play in may DIY projects, making 4" thick material a very cost effective solution to most acoustic treatment projects. On another note, the increase of material thickness from 2" to 4" for regular wall acoustic panels shows that the absorption of mid to high range frequencies is not improved.

*Differences of coefficients less than 0.15 are not significant HARDWARE OPTIONS FOR EASY INSTALL:

CLICK HERE FOR OUR DIY ACOUSTIC WALL PANEL GUIDE

|